Wire Straightening And Cutting Machine 2-6mm

The Wire Straightening And Cutting Machine 2-6mm is a specialized equipment designed for precision processing of wires within the diameter range of 2 to 6 millimeters. It boasts adjustable wire diameter and cutting length capabilities, ensuring versatility across various applications. Equipped with an advanced straightening die system, this machine ensures that the output wires are exceptionally straight, enhancing product quality. Furthermore, its intuitive operation and stable working performance make it a user-friendly solution for efficient wire processing, streamlining production processes.

Our News

Meet DAPU Machinery at Wire Eurasia 2025 – Booth 742B

DAPU Machinery will attend Wire Eurasia 2025 in Istanbu [...] [...]

Working Process & Advantages

Advantages

1.Wire diameter and cutting length can be adjusted.

2.Straightening die system, wire is more straight.

3.Easier to operate, working stable.

Technical Parameters

| Model | GT2-6 |

| Wire diameter | 2mm-6mm |

| Cutting length | 100-6000mm |

| Speed | 30m/min |

| Straight motor | 2.2kw |

| Cut motor | 1.5kw |

| Cut error | ±1mm |

| Overall size | 7.2X0.5X0.9m |

| Weight | 270kg |

After-sales service

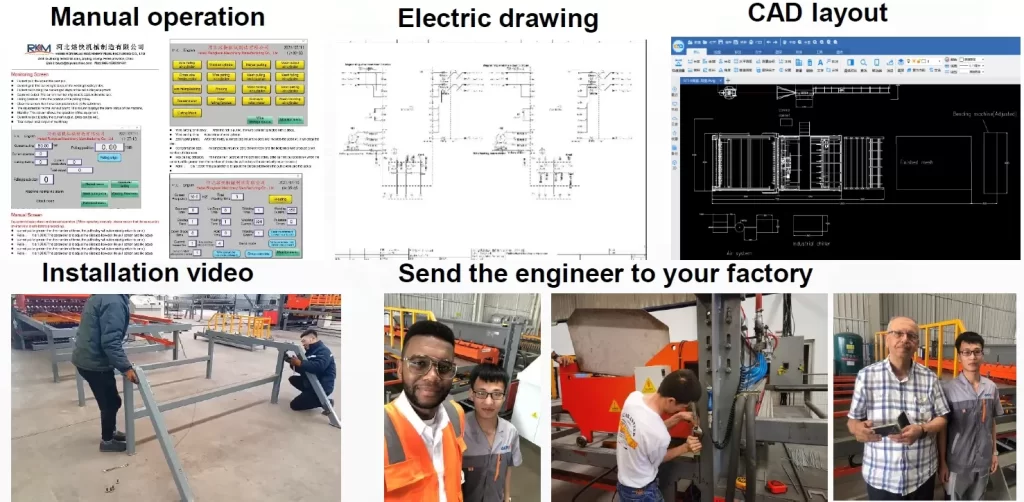

- Comprehensive Documentation Package:

- Offer exhaustive manuals for easy reference, detailing every aspect of operation.

- Provide intricate electrical schematic diagrams for in-depth understanding of system components.

- Include CAD blueprints for accurate planning and installation.

- Supply comprehensive installation videos, guiding through each step for hassle-free setup.

- Round-the-Clock Technical Support:

- Grant access to our skilled team of technicians for uninterrupted online assistance.

- Ensure prompt responses to any inquiries or issues, 24/7.

- Warranty-Covered Spare Parts Replacement:

- Offer complimentary replacement of any faulty spare parts within the warranty timeframe.

- Maintain machine efficiency and minimize downtime due to unexpected breakdowns.

- On-Site Installation & Staff Training:

- Dispatch seasoned engineers to your premises for professional on-site machine installation.

- Conduct staff training sessions to ensure seamless and proficient operation post-installation.

- Ensure a smooth transition from installation to full-fledged operation.