High Speed Wire Straightening And Cutting Machine 3-6mm/3-8mm/5-10mm

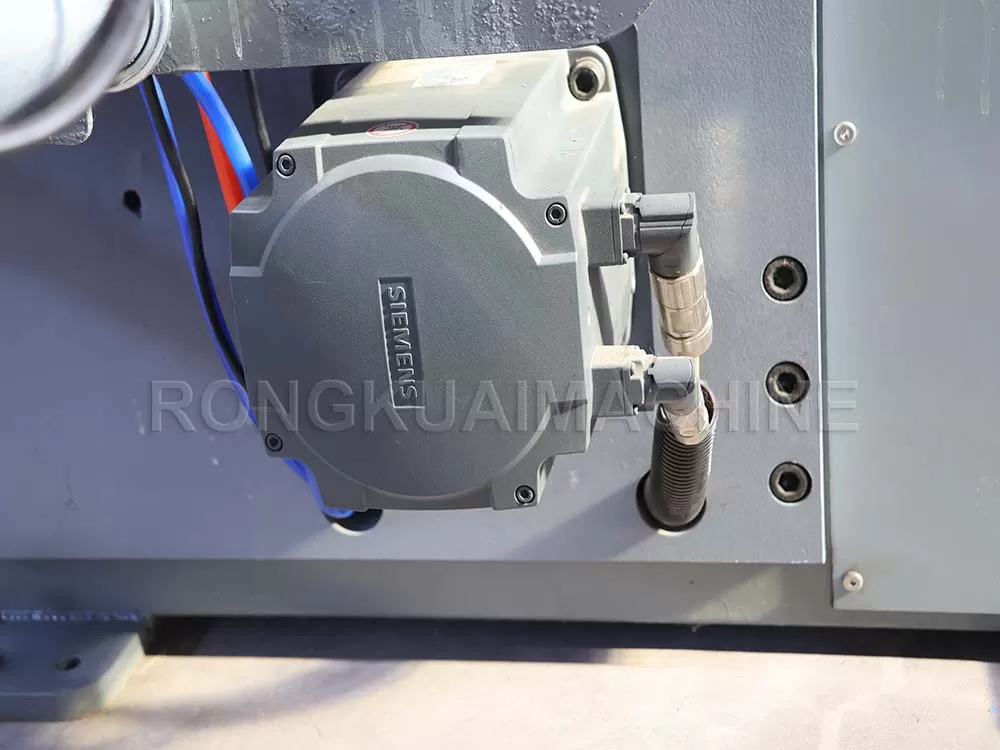

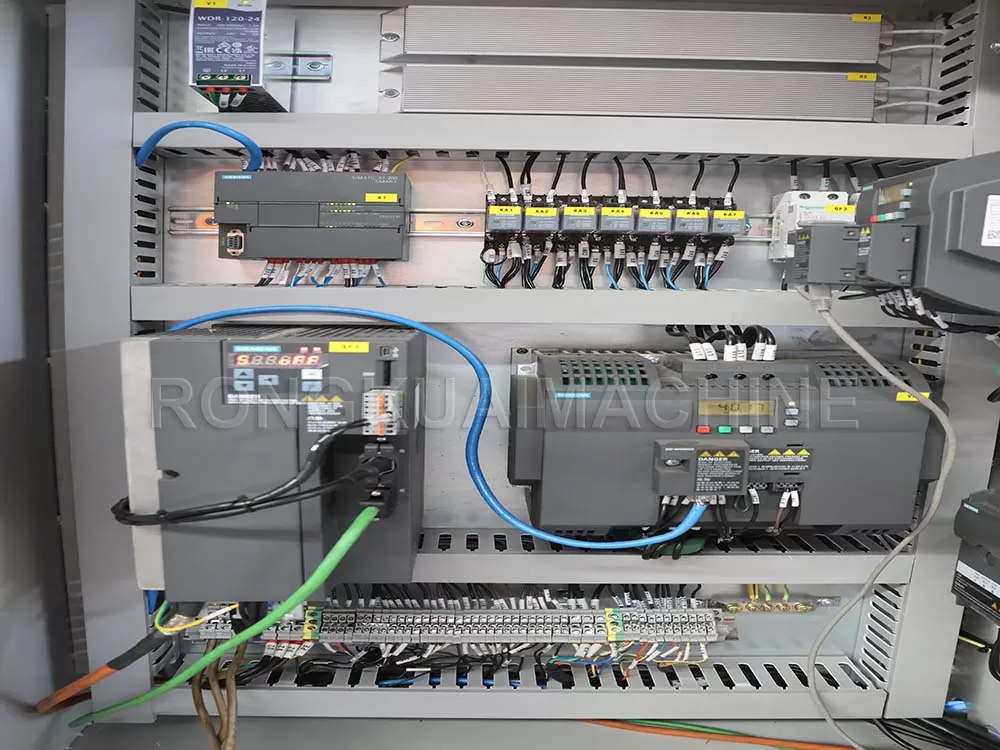

The High Speed Wire Straightening And Cutting Machine, suitable for 3-6mm/3-8mm/5-10mm wires, features Siemens PLC & touchscreen, servo-driven cutting, inverter-controlled speed. Equipped with SMC air cylinder for traction control and Siemens-branded components, it ensures precise straightening and cutting, producing high-quality straight wires.

Our News

Meet DAPU Machinery at Wire Eurasia 2025 – Booth 742B

DAPU Machinery will attend Wire Eurasia 2025 in Istanbu [...] [...]

Working Process & Advantages

Advantages

1.Siemens PLC+Siemens touch screen

2.Servo motor to control wire cutting

3.Inverter to control working speed.

4.SMC air cylinder to control wire tranction.

5.Main motor, inverter, servo motor, breaker Simens brand option.

6.Straightening die system, wire is more straight.

Technical Parameters

| Model | GT3-6H | GT3-8H | GT5-10H |

| Wire diameter | 3-6mm | 3-8mm | 5-10mm |

| Cutting length | 330-6000mm+ | 330-6000mm+ | 800-6000mm+ |

| Speed | Max.130m/min | ||

| Straightening motor | 7kw with inverter | 15kw with inverter | 22kw with inverter |

| Cutting motor | 2.9kw servo motor | 3kw servo motor | 5.5kw servo motor |

| Cut error | ±1mm | ||

| Overall size | 12*1*1.2m | 12*1.1*1.25m | 12*1.2*1.35m |

| Weight | 1500KG | 1800KG | 2000KG |

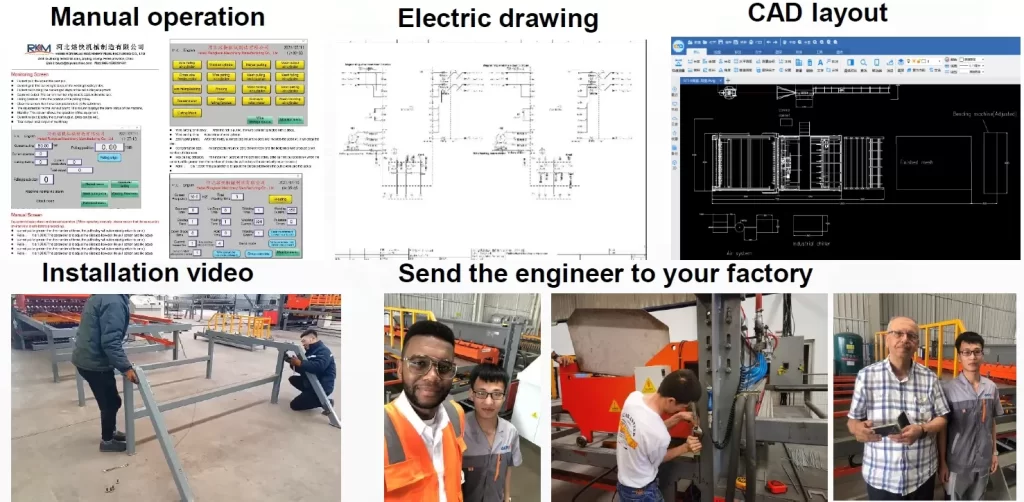

After-sales service

1.Manual handling capabilities, electric drafting services, CAD layout design, and installation video guides.

2.Dedicated online technical support provided by our skilled technicians.

3.Free replacement of defective spare parts during the warranty period.

4.On-site engineer dispatch for machine installation and comprehensive operator training at your facility.