Steel Rebar Straightening And Cutting Machine 5-12mm/8-14mm/10-16mm

The Steel Rebar Straightening And Cutting Machine, capable of processing 5-12mm/8-14mm/10-16mm diameters, boasts precision CNC control for cutting length and quantity, ensuring accuracy. Optional inverter integration allows for flexible adjustment of working speeds, enhancing productivity. Equipped with an advanced straightening roller system, it minimizes wire surface damage, ensuring consistent quality output. This machine is the professional's choice for efficient rebar processing.

Our News

Meet DAPU Machinery at Wire Eurasia 2025 – Booth 742B

DAPU Machinery will attend Wire Eurasia 2025 in Istanbu [...] [...]

Working Process & Advantages

Advantages

1.Siemens PLC+Siemens touch screen

2.Servo motor to control wire cutting

3.Inverter to control working speed.

4.With wire slope block device

5.Straightening die system, wire is more straight.

Technical Parameters

| Model | GT5-12 | GT6-12H | GT8-14 | GT10-16 |

| Wire diameter | 5-12mm | 6-12mm | 8-14mm | 10-16mm |

| Cutting length | 1000-12000mm | |||

| Speed | Max.130m/min | |||

| Straightening motor | 30kw with inverter | 37kw with inverter | 37kw with inverter | 45kw with inverter |

| Cutting motor | 7.5kw servo motor | |||

| Cut error | ±1mm | |||

| Weight | 4500KG | 4800KG | 5100KG | 5500kg |

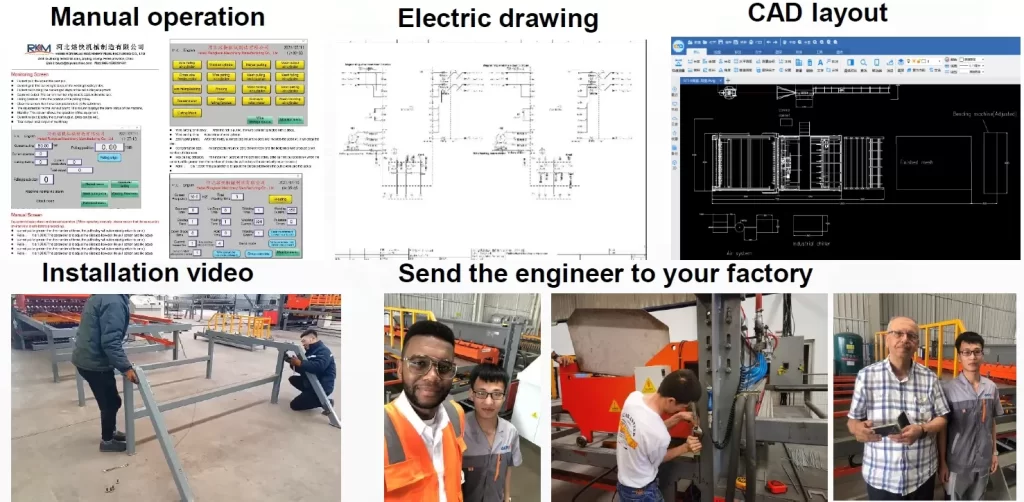

After-sales service

1.Manual handling capabilities, electric drafting services, CAD layout design, and installation video guides.

2.Dedicated online technical support provided by our skilled technicians.

3.Free replacement of defective spare parts during the warranty period.

4.On-site engineer dispatch for machine installation and comprehensive operator training at your facility.