Reinforcement Mesh Welding Machine 3-8mm

Our News

Meet DAPU Machinery at Wire Eurasia 2025 – Booth 742B

DAPU Machinery will attend Wire Eurasia 2025 in Istanbu [...] [...]

Working Process

Technical Parameters

| Model | DP-FM-2500A/DP-FM-3000A |

| Wire diameter | 3-8mm |

| Line wire spacing | 100-250mm |

| Cross wire spacing | 50-300mm |

| Mesh welding width | Max.2500mm/3000mm |

| Mesh length | Max.6m/12m |

| Welding points | 24pcs/30pcs |

| Welding speed | Max.80-100 times/min |

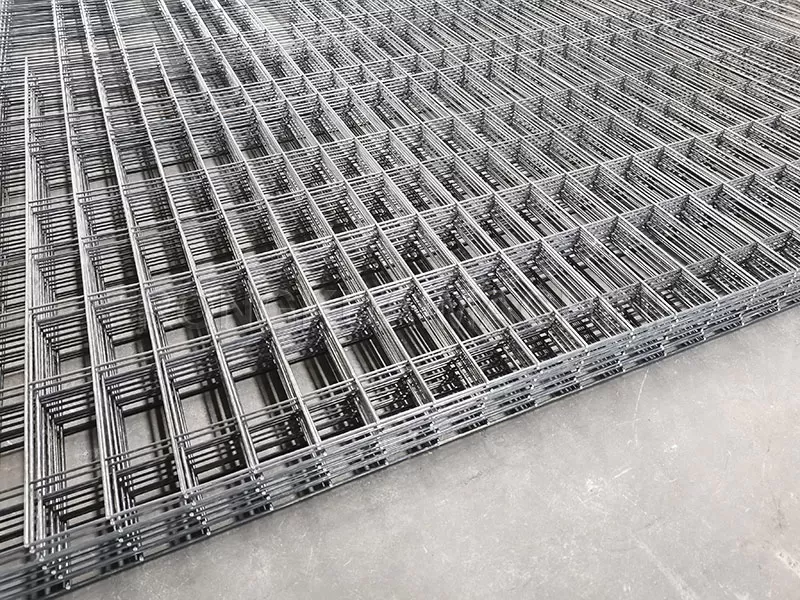

Actual Production

| Dia | Spacing | W*L | Line wire

No. |

Cross wire No. | Wire length on one mesh | One Mesh weight | Production | |

| 4mm | 150x150mm | 2.4x6m | 16 | 40 | 192m | 19.0KG | 55pcs/hour | 1045KG/hour |

| 5mm | 150x150mm | 2.4x6m | 16 | 40 | 192m | 29.6KG | 55pcs/hour | 1628KG/hour |

| 6mm | 150x150mm | 2.4x6m | 16 | 40 | 192m | 42.6KG | 55pcs/hour | 2343KG/hour |

| 8mm | 150x150mm | 2.4x6m | 16 | 40 | 192m | 75.8KG | 55pcs/hour | 4169KG/hour |

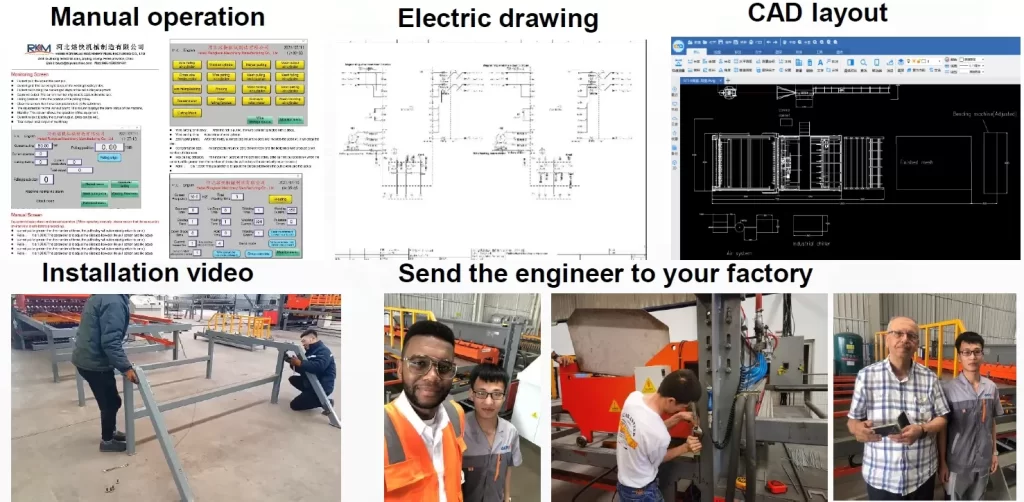

After-sales service

- Provide comprehensive guides for manual operation, electric schematics, CAD layouts, and installation videos to ensure easy and accurate setup and operation.

- Online technical support from our expert technicians to assist with any issues or queries.

- Replace any damaged spare parts free of charge during the warranty period, ensuring the machine’s optimal performance and longevity.

- Dispatch skilled engineers to your facility for on-site machine installation and training, ensuring proper setup and efficient operation.

Auxiliary unit

Air compressor, air tank, drier and filters

Industrial-chiller

Cold-rolling-steel-rebar-ribbed-machine

RFQ

1.What’s the consume part on your machine? What’s the material of it? How long should change?

Welding electrode

Upper welding electrode 25*25*30mm; Lower welding electrode 25*25*30mm

Material: chromium zirconium copper.

The service life depends on the welding degree and wire diameter you mainly use. Normally 4-8 months.

2.Space needed for your machine?

With automatic mesh falling system, around 28m length, 9m width

Without automatic mesh falling system, around 25m length, 9m width

3.How many labors needed?

With automatic mesh falling system, 2 workers. One is for feeding longitude wires, the other one is for feeding cross wire, check mesh welding and pulling.

Without automatic mesh falling system, 3-4 workers. One is for feeding longitude wires, one is for feeding cross wire, check mesh welding and pulling, 1-2 workers for pulling out mesh.

4.To change mesh size for example 100*100-150*150mm, how can we do it?

For line wire space 100mm change to 150mm, need to move the air cylinders, welding electrodes, lower copper plates. For cross wire space 100mm change to 150mm, only need to change the data on touch screen.

- 5. If change 6mm wire to 8mm wire, what should I do?

For line wires, adjust the slot tunnel, loosen the screw and make the opening to suit 8mm.

For cross wires, adjust the gap of cross wire feeding wheel.

Then, increase the welding parameter to suit 8mm

- 6. Delivery time?

Delivery within 30-40 days after receiving the advance payment